What is Laser Engraving?

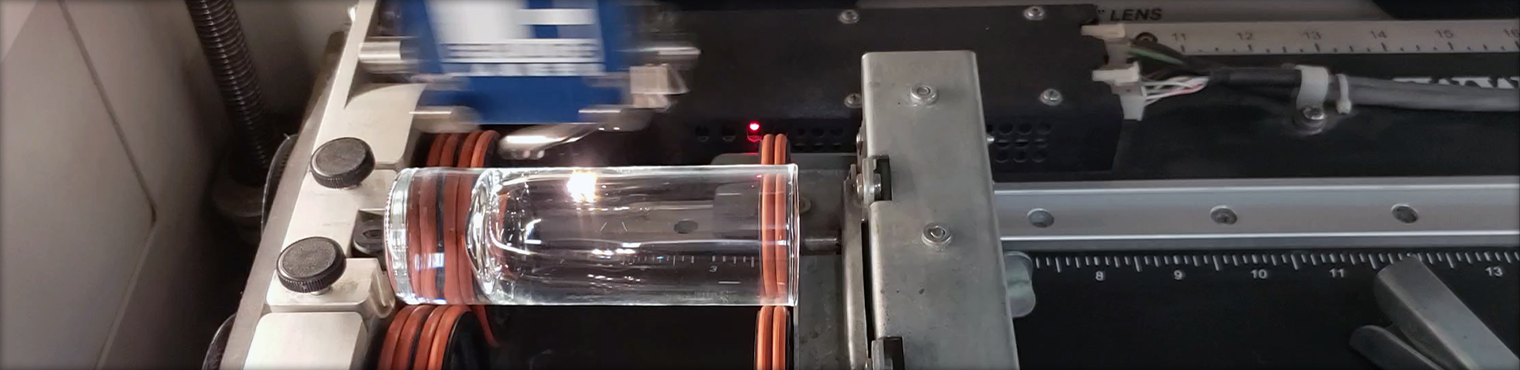

Laser engraving is a fast, affordable process that allows our clients to create unique and personal items for business, industrial and personal use. Laser engraving involves the use of focused laser beams to change the surface of a material made from glass, plastic, wood, acrylic, and metals such as aluminum, brass, copper, steel alloys, and many more materials. During the laser engraving process, the laser beam removes a thin surface layer of the material to create a cavity in the shape of the desired image. The heat from the laser beam “vaporizes” the material, and forms deeper marks that can be seen with the eye and felt by touch.

Our products can be customized by adding logos, graphics, names and more. We offer the same affordability to engrave, or etch on your items and products too! We provide laser engraving services with quick turnaround times to permanently mark various products using precision laser technology. With both CO2 and Fiber Lasers we have the capability to customize many different types of products. CO2 lasers work best for engraving on wood, glass, acrylic and many other materials. Fiber lasers are ideally suited for metal marking and removing the coating from metal products. If a product isn’t suitable for permanent marking with traditional methods, we offer solutions with a chemical bonding agent known as CERMARK or THERMARK. At Krios, we regularly use these methods on surgical items or industrial specific needs.

The Difference Between Laser Engraving and Laser Etching?

Laser engraving and etching are very closely related processes, but there are some varied differences. The best way to explain it would be to describe a piece of glass that the laser would slightly fracture the surface of the glass to give it an etched, or frosted look. Think of it as a very slight amount of material being chipped, or removed from the surface without penetrating deep into the surface of the glass. While both processes use lasers to create markings, engraving creates much deeper markings than those produced by etching. This is ideal for high wear parts on which other markings may be worn off over time. Laser engraving also generates more heat than etching, which can make it less compatible with thinner or more sensitive materials like glass.

Benefits of Using A Laser Engraving Service

Compared to marking products with ink, laser engraving is much more precise and environmentally friendly, requires no drying time, and is permanent. Benefits include:

• Laser engraving can produce artistic results. You can add graphics, logos, quotes, smart codes, brand names, and much more.

• Long-Term longevity, durability both indoors and outdoors

• Better Legibility

• Provides functional information for components

CO2 LASER COMPATIBLE MATERIALS

| MATERIAL | ENGRAVE | CUT |

|---|---|---|

| Wood | x | x |

| Acrylic | x | x |

| Fabric | x | x |

| Glass | x | |

| Coated Metals | x | |

| Ceramic | x | |

| Delrin | x | x |

| Cloth | x | x |

| Leather | x | x |

| Marble | x | |

| Matte Board | x | x |

| Melamine | x | x |

| Paper | x | x |

| Mylar | x | x |

| Press Board | x | x |

| Rubber | x | x |

| Wood Veneer | x | x |

| Fiberglass | x | x |

| Painted Metals | x | |

| Tile | x | |

| Plastic | x | x |

| Cork | x | x |

| Corian | x | x |

| Anodized Aluminum | x | |

| Stainless Steel | * | |

| Brass | * | |

| Titanium | * | |

| Bare Metals | * |

*CO2 lasers will mark bare metals when coated with a metal marking solution.

FIBER LASER COMPATIBLE MATERIALS

| Mark / Engrave | |

|---|---|

| 17-4 PH Stainless Steel | x |

| 303 Stainless | x |

| 4043 Steel | x |

| 6061 Aluminum | x |

| Bayer 2807 Makrolon polycarbonate | x |

| Bayers Bayblend FR 110 | x |

| Black/White ABS | x |

| Brass | x |

| Brushed Aluminum | x |

| Carbon Nanotube | x |

| Clear Coat Anodized Aluminum | x |

| Cobalt Chrome Steel | x |

| Colored Delrin (Black/White) | x |

| Compacted Powder Iron w/Iron Phosphate Coating | x |

| Copper | x |

| DAP – Diallyl Phthalate | x |

| GE Plastics Polycarbonate Resin 121-R | x |

| Glass Filled PEEK | x |

| Glass Filled Telfon | x |

| Hard Coat Anodized Aluminum | x |

| Machine Tool Steel | x |

| Magnesium | x |

| Metal Plated Ceramics | x |

| Molybdenum | x |

| Nickel Plated 1215 Mild Steel | x |

| Nylon | x |

| Polybutylene Terephthalate | x |

| Polysulphone | x |

| Rynite PET | x |

| Santoprene | x |

| Silicon Carbide | x |

| Silicon Steel | x |

| Silicon Wafers | x |

| Various Inconel Metals (Nickel-Chromium Super Alloys) | x |

| White PEEK | x |

| Yellow Chromate Aluminum | x |

| Zinc Plated Mild Steel | x |